Alain Désiré, CEO of Hytem, was asked about the implementation of new software within the company improving the data capture from network analyzers, thanks to Smart Industry Support (ASI) Île-de-France.

Find the details of the article below ⤵

Hytem manages its digital transformation

When you are the manager of a small company, you are always rushing and you have to address all subjects, notes Alain Désiré, general manager of Hytem since 2013, after having been its commercial director from 1999.

ASI Île-de-France was an opportunity for me to make a diagnosis of the company, to see if the ideas for improvement I was thinking of were feasible”. Specialized in the manufacturing and distribution of electronic systems and components in the field of radio frequencies and microwaves, Hytem addresses many sectors such as telecoms, military, rail and air transportation,…

“With the help of a first consultant, we listed around ten technological bricks that could be put in place, explains Alain Désiré. We selected two of them and I chose to focus on the one that seemed to me the most reasonable for a first stage of digital transformation”.

Save time, fewer errors and better customer service

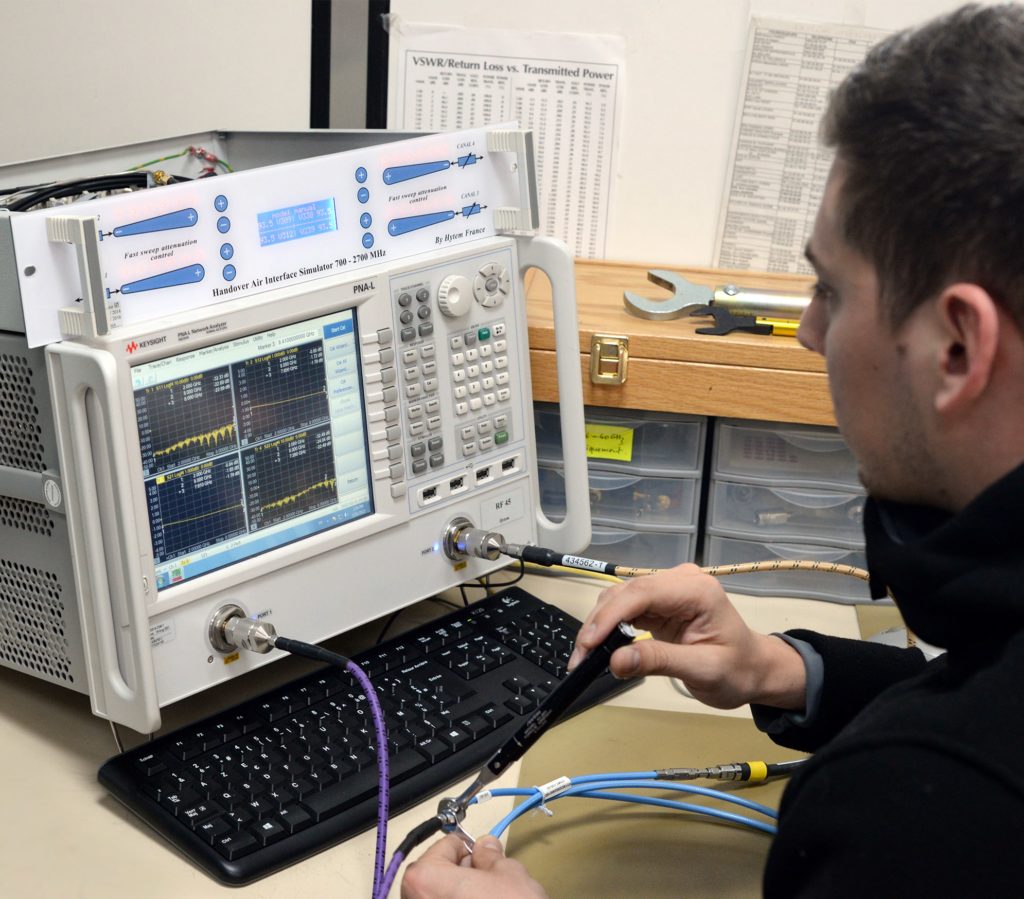

This is how the general manager of Hytem decided to streamline the process of recording measurements (coaxial cords and components) on network analyzers by installing new software.

“Until then, the operator had to measure, then take a screenshot, transfer it to the computer, convert it to PDF and electronic file, store it in the right folder…, explains Alain Désiré. The service provider recommended by the UPS Ile-de-France consultant therefore established the necessary software specifications that would allow us to divide the time allocated to this phase by 5, by automating the process: now, the operator does not have to all that’s left is to perform the measurement and transfer the data, which is automatically placed in the right folder”.

By reducing the number of tasks to be performed, Hytem teams save time and reduce the risk of errors, while offering customers better service. “The data is recorded and available as soon as we are asked for it, whereas before, we generally had to redo the measurement to send it”. For Alain Désiré, this experience showed the way. “We now know how it works with outside intervention and how it is possible to improve our processes.”

The action

Smart Industry support, funded by the Île-de-France Region, is aimed at SMEs/SMIs carrying out a production activity in Île-de-France. The system allows them to benefit from support provided by experts to improve their overall competitiveness by playing on both operational excellence and the potential of the industry of the future. Since the health crisis, two courses have been created. One to secure its activity and the other to adapt to new economic conditions following the Covid crisis.

To view the original article, click here.